Integrating robotics systems involves tackling several challenges you’ll need to address. Sensor synchronization is critical for accurate environmental perception, but misaligned timing can cause data issues. Software compatibility often requires extra middleware or updates, especially with legacy systems. Implementation and testing can be time-consuming, as unexpected issues may arise. Additionally, training your team is essential to ensure smooth operation. Continuing will help you understand effective strategies to overcome these hurdles and achieve seamless integration.

Key Takeaways

- Ensuring precise sensor synchronization to enable accurate environmental perception and reliable data fusion.

- Overcoming software compatibility issues between new hardware and legacy control systems.

- Addressing implementation and testing complexities to prevent system failures post-deployment.

- Providing adequate training for personnel to operate and troubleshoot advanced robotic components effectively.

- Developing strategies to overcome technical barriers and achieve seamless interoperability among diverse robotic systems.

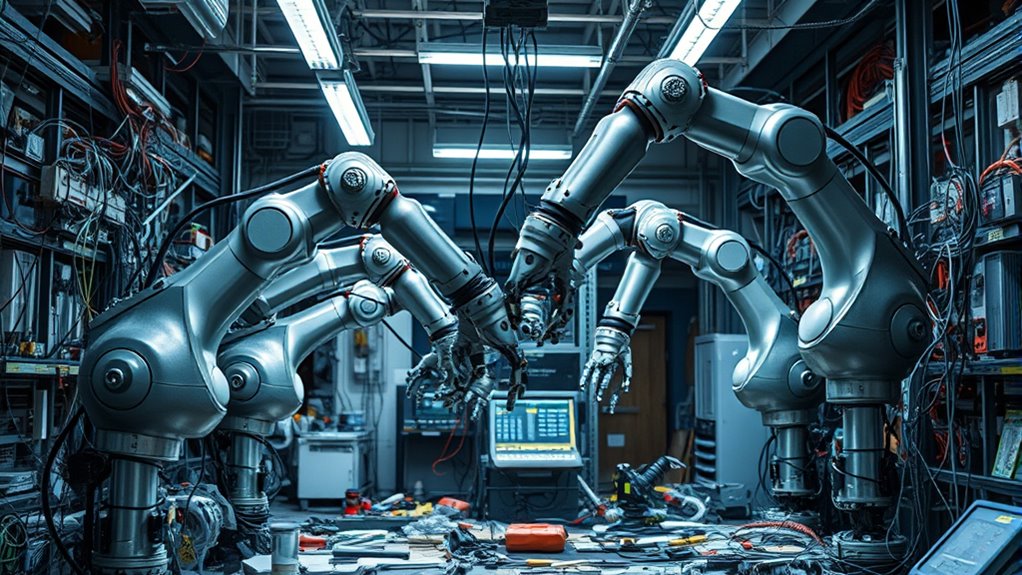

Integrating robotics into existing systems often presents significant challenges that can hinder smooth implementation. One of the most critical hurdles is ensuring sensor synchronization. When you bring new robotic components into a system, they rely heavily on sensors to perceive their environment accurately. If these sensors aren’t properly synchronized, the robot may misinterpret data or respond too slowly, leading to errors or safety issues. Achieving seamless sensor synchronization requires precise timing and calibration between the robot’s sensors and the current system. Any lag or mismatch can cause inconsistent data flow, making it difficult for the robot to operate reliably. You need to carefully plan how sensors communicate and coordinate, often involving complex timing protocols and calibration routines. Overcoming sensor synchronization issues demands thorough testing and fine-tuning, which can be time-consuming but is essential for dependable operation.

Another major obstacle is software compatibility. When integrating robotics, you often face the challenge of making the new hardware and software work with existing control systems. Different manufacturers may use proprietary software, or the system’s legacy software might not support the new robotic components out of the box. You might find yourself juggling multiple software platforms or struggling to update legacy systems without disrupting ongoing operations. Compatibility issues can cause delays, increase costs, and sometimes even require significant reprogramming. To address this, you need to evaluate whether your current system supports the new robot’s software or if you’ll need middleware solutions to bridge compatibility gaps. Ensuring compatibility often involves custom programming, software updates, or adopting open standards that facilitate integration. It’s vital to test thoroughly in controlled environments before full deployment, as overlooked compatibility issues can lead to system failures or inefficiencies.

Additionally, you should consider that integrating robotics isn’t just about hardware and software; it’s also about the human element. Your team needs to understand the new systems, and training might be necessary to operate and troubleshoot the robots effectively. As you work through sensor synchronization and software compatibility, you’ll likely encounter unforeseen issues that require quick problem-solving and adaptability. Planning for these challenges from the outset can help smooth the transition, but be prepared for a learning curve. In the end, the goal is to create a cohesive system where robotic components communicate flawlessly and perform tasks reliably, but achieving that harmony often involves overcoming complex technical barriers. Recognizing these challenges early on and understanding the importance of system interoperability can help develop strategies that minimize disruptions and maximize the benefits of robotic integration.

Frequently Asked Questions

How Do I Select the Right Robotics Platform for My Business?

To select the right robotics platform for your business, start by evaluating your specific needs and goals. Focus on robotics hardware that fits your tasks and guarantee the software compatibility aligns with your existing systems. Consider scalability, ease of integration, and vendor support. Test different options if possible, and choose a platform that offers reliable performance and future growth potential, helping you streamline operations effectively.

What Are the Cost Implications of Integrating Robotics Systems?

Integrating robotics systems is like planting a seed—your initial investment can grow considerably. You’ll need to do a thorough cost analysis, considering upfront costs, maintenance, and training. While the investment may seem high, the potential for increased efficiency and faster ROI makes it worthwhile. Remember, smart planning ensures you maximize your investment return, turning your robotic system into a valuable asset rather than a costly burden.

How Can I Ensure Staff Acceptance of Robotics Technology?

To facilitate staff acceptance of robotics technology, you should focus on effective change management by clearly communicating benefits and addressing concerns. Offer thorough employee training to build confidence and skills, making the shift smoother. Involve staff early in the process, encouraging feedback and participation. This approach fosters trust, reduces resistance, and helps your team see how robotics can enhance their work, ultimately leading to smoother integration and acceptance.

What Cybersecurity Risks Are Associated With Robotics Integration?

You face cybersecurity threats like data breaches when integrating robotics. Hackers could access sensitive information or manipulate robot operations, causing safety and security risks. To protect your systems, implement strong firewalls, regular security updates, and robust access controls. Educate staff on cybersecurity best practices, and monitor networks continuously for suspicious activity. Taking these steps helps safeguard your robotics environment from potential cyber threats and maintains operational integrity.

How Do I Handle Future Scalability of Robotics Systems?

To handle future scalability of robotics systems, you should prioritize scalability planning and implement future-proofing strategies. Assess your current infrastructure, anticipate growth, and select modular, flexible components that can adapt to evolving needs. Regularly review and update your systems, invest in scalable software solutions, and maintain a proactive approach to technology upgrades. This guarantees your robotics infrastructure can grow seamlessly with your business, minimizing disruptions and optimizing long-term performance.

Conclusion

As you navigate robotics integration, remember it’s like trying to fit a square peg into a round hole—challenging but rewarding. Embrace the hurdles as your modern-day Odyssey, where perseverance leads to innovation. By addressing communication gaps, technical snags, and workflow disruptions, you’ll forge ahead like a seasoned pioneer. Keep pushing forward, knowing that overcoming these obstacles will transform your operations into a sleek, futuristic machine—almost like having a robot sidekick in your corner.